VALVE MAINTENANCE, REPAIRS & TESTING SERVICES

VALVE SERVICES

QUALITY SYSTEM

The purpose of the Quality Control Program of PANSA MACHINE SHOP N.V. is to ensure compliance with the requirements of the ASME Code and National Board Inspection Code.

The “VR” Stamp shall be applied only to valves which are stamped with the ASME Certification Mark with the “UV” designator or the supplanted “UV” Code symbol and have been capacity certified by the National Board. Such valves shall have been disassembled, inspected, repaired, tested and sealed in order to verify condition and performance equivalent to the standards for new valves.

Pressure Relief Valves for Test Only shall have been visually inspected and successfully tested. Only external adjustments to restore Pressure Relief Valve Nameplate Set Pressure and or performance have been made.

SCOPE OF OPERATIONS

- Valve Maintenance Management Services

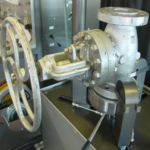

- In-Situ and Workshop Block Valve Repair and Maintenance

- In-Situ and Workshop Pressure Safety Valve (PSV) Repair, Testing and Certification

- Control Valve and Actuator Service and Repair

- Assembly and Installation as well as Design Engineering

- Reliability Inspection Services

VALVE SERVICES

- In-Situ Shut Off Valve Maintenance

- In-Situ Pressure Relief Valve Testing and Certification

- Off Site Relief Valve Testing and Certification

- Preventative and Predictive Maintenance

- Valve & Actuator Sizing, Engineering Design & Change Out

- Computerized Valve Asset Maintenance Management

- Online Valve Certification

- Valve & Actuator Supply

- Valve Maintenance and Safety Training

- Workshop Shut Off Valve Repair & Maintenance

- Workshop Control Valve Repair & Maintenance

- Workshop Pressure Relief Valve Testing and Certification

- In-Situ Control Valve Repair & Maintenance

- Actuator Repairs, Testing and Certification

VENTIL COMPUTERISED VALVE TESTING UNIT

Our Computerized Test Bench is capable of Pressure Testing Valves: Ball, Butterfly, Globe, Gate etc. and Certifying the Set Pressure of Pressure Safety Valves and Pressure Relief Valve. All tests are in accordance with one or more of the following International Test Standards:

National Board of Boiler and Pressure Vessel Inspectors Code:

- API 527- Seat Tightness of Pressure Relief Devices, 4th Edition November 2014

- NB 18- National Board Pressure Relief Device Certifications

- ASME 2017 section VIII Division 1

- ANSI/NBIC 2017- part 1 – part 4

- ASME PTC 25-2014- Pressure Relief Devices

- NB-528- Accreditation of ‘’T/O’’ Test only and ‘’VR’’ repair organizations

- ASME- NBIB- R stamp: Repairs and alterations

Valve Project Fernandes

Certified industrial manufacturing, construction steel, fabrication of power boilers, pressure vessels, skid units, tanks, silo’s and pontoons. Pump & valve repairs and parts manufacturing (shafts/impellers/stems) shut off, control & safety valve testing and certification, replacement and installation of pump & motor bearings, balancing of impellers, electrical motor service and repair.

PANSA GROUP OF COMPANIES N.V.

Address: Martin Luther King Highway km 23

Para - Suriname (South - America)

Phone: (+597) 6802051 / (+597) 6802052

Mobile: (+597) 7698047 / (+597) 7698050

Email: info@pansamachinery.com

© 2019-2020 Pansa Group of Companies N.V. All rights reserved, their respective logos, as well as company and product names used here, are trademarks of Pansa Holding and may not be used without permission.

Design by Suritargets